Some Thoughts on Five-in-One Laser Welding Machines

From a salesperson with 8 years of experience in the laser industry

This is not a formal article.

These are more like some thoughts based on my personal experience. I've worked in sales in the laser equipment industry for about eight years, during which I've communicated with many customers from different countries. What I'm writing here is just some observations I've made and things I've heard in my daily work. I hope it will be helpful to you.

In the past few years, I've noticed that five-in-one laser welding machines are appearing more frequently than before. They mostly appear in small workshops, not in factories with production lines, but in places where welding, cutting, repairing, and cleaning metal parts are all done in the same work area.

This is also why many customers are starting to inquire about these types of machines.

Why do people ask about these types of machines?

Typically, the conversation doesn't start with "five functions."

Instead, the conversation begins with simple questions such as:

"We don't have much space."

"We do different jobs every week."

"We don't want to have too many machines in the workshop."

In many small workshops, welding, cutting, and finishing are all done on the same workbench. While people don't always realize it, moving workpieces from one machine to another takes time.

Therefore, when customers see a machine that can perform multiple processes, they become interested. This isn't because the machine is perfect, but because it seems easier to manage.

Welding remains the primary application.

From my observation, most customers primarily use this machine for welding.

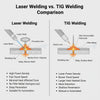

Stainless steel, carbon steel, and basic fabrication work are the most common applications. Laser welding technology is already familiar to many users, so there are no surprises here. The welds are narrow, with minimal distortion, and usually require little to no post-weld grinding.

Other functions are used only when needed, not on a daily basis.

For example, the cutting function is mainly used for thin materials, edge trimming, or making minor adjustments. It's not as fast as a large laser cutting machine, but it's very useful when quick function switching is required.

Cleaning work may seem insignificant, but it can save time.

Initially, many people don't pay much attention to cleaning.

However, after using the machines for a while, they realize that manually removing rust, oxides, or welding discoloration requires a lot of effort. Moreover, the cleaning effect largely depends on the operator's skill. Some do it well, others don't.

Laser cleaning cannot completely replace manual work, but it can significantly reduce the amount of manual labor. This is especially true for stainless steel products, where the appearance is often more important than many customers initially anticipate.

Battery welding issues are being raised with increasing frequency.

Recently, battery welding has been discussed more and more often.

These questions don't come from large battery factories. These factories have completely different equipment and requirements.

Most of the questions come from repair shops or customers who make small battery packs. They ask about how to weld battery terminals, nickel tabs, or connectors. Temperature control is very important in this type of work, and laser welding is very helpful, especially for small-scale operations.

Most customers understand that this function is suitable for repair, testing, or small-batch production, not for large-scale manufacturing.

Concluding Remarks

This is not a conclusion, but merely an observation based on daily sales work.

The interest in five-in-one laser welding machines is not solely driven by marketing. This interest stems from actual needs in production workshops, such as limited space, insufficient manpower, and the need to accomplish different tasks with fewer pieces of equipment.

This article is based on my daily communication with customers and real workshop feedback.