✨ Key Features

- ✅ No chemical cleaning required, eco-friendly and safe

- ✅ Non-contact cleaning, no damage to the substrate

- ✅ Easy to operate, plug and play

- ✅ Suitable for various materials like metal, stone, concrete, etc.

- ✅ Precise positioning for selective cleaning

- ✅ Portable design, supports handheld or robotic arm integration

- ✅ Long laser lifespan, stable performance

💬 Customer Feedback

- 🌟 “Works perfectly for rust removal, saved hours of manual work!” – Ahmed, UAE

- 🌟 “We cleaned old paint from large steel surfaces easily. Very powerful.” – Carlos, Spain

- 🌟 “Impressed with the precision and no damage to parts.” – Peter, Germany

- 🌟 “Very good quality and fast delivery, highly recommended.” – Mohamed, Egypt

Laser Cleaning Machine Specifications

| Parameter | Specification | Description |

|---|---|---|

| Model | CL-1500 / CL-2000 / CL-3000 | Multiple models to suit different industrial cleaning needs |

| Laser Power | 1500W / 2000W / 3000W | Higher power for deeper and faster cleaning |

| Laser Type | Fiber Laser | High-efficiency, low-maintenance laser source |

| Wavelength | 1064 nm | Standard for metal surface cleaning |

| Cleaning Width | 10–100 mm | Adjustable according to material and settings |

| Cleaning Depth | Up to 1.2 mm | Suitable for rust, paint, and oxide layer removal |

| Cooling Method | Water Cooling | Ensures stable performance during continuous operation |

| Power Supply | AC 220V ±10%, 50/60Hz | Industrial standard single-phase power |

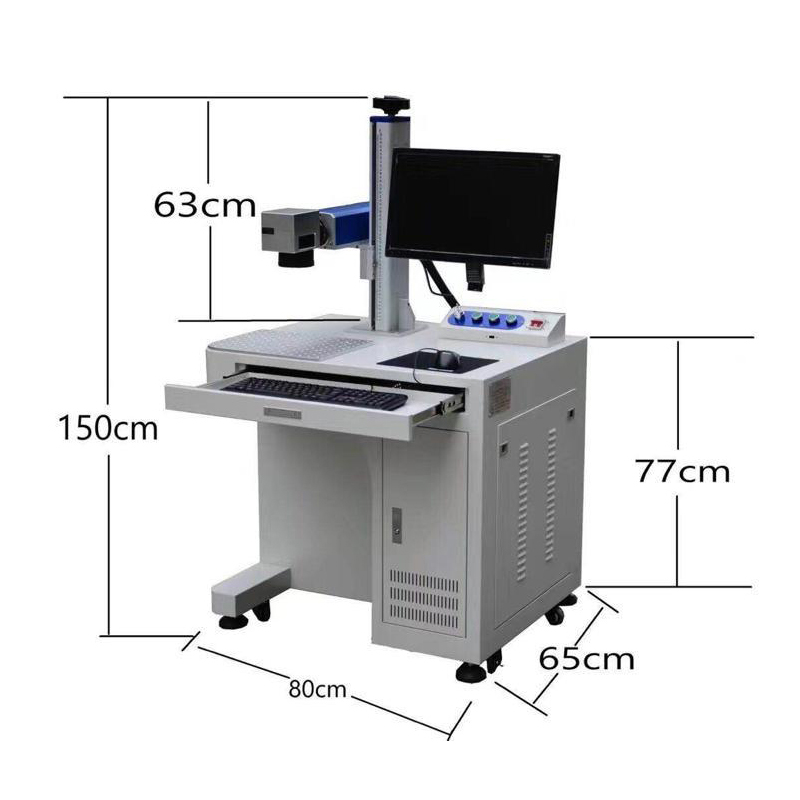

| Machine Size | 1000 × 700 × 1400 mm | Compact, movable and space-saving |

| Weight | Approx. 120 – 150 kg | Varies with model and configuration |

| Supported Materials | Metal, paint, rust, oil, coatings, oxide layers | Ideal for pre-treatment and restoration |

| Application Fields | Automotive, shipbuilding, aerospace, molds, restoration | Widely used across heavy and precision industries |

| Optional Features | Handheld gun, auto-focus, robot arm, fume extractor | Flexible upgrades to meet customized needs |

For more details, click here to contact us on WhatsApp.

Fiber laser cleaning machine uses a high-energy laser beam to remove rust, paint, oil, oxide, and other contaminants from metal surfaces without damaging the substrate. Compared with traditional cleaning methods (chemical, abrasive), laser cleaning is non-contact, eco-friendly, and low-maintenance.

It’s widely used in industries such as:

Automotive

Aerospace

Shipbuilding

Mold and injection industries

Power generation (turbines, pipes)

Restoration of cultural relics