| Parameter | Specification | Description |

|---|---|---|

| Laser Type | Fiber Laser / YAG Laser (optional) | High-quality laser source suitable for precision welding, cutting, and cleaning |

| Laser Power | 1500W / 2000W / 3000W | Adjustable power options for different material thickness and welding requirements |

| Welding Speed | 0 – 1200 mm/s | Variable speed control to ensure high efficiency and quality welding |

| Welding Thickness | 0.1 – 10 mm (depending on material and power) | Suitable for thin to medium thickness metal welding |

| Working Area | 300 x 300 mm / 400 x 400 mm / Customizable | Standard and customizable working area options to fit different workpieces |

| Welding Mode | Continuous / Pulsed | Allows precision control over weld penetration and heat input |

| Cutting Capability | Supports thin metal sheets up to 3mm | Integrated cutting function for versatile applications |

| Cleaning Function | Laser surface cleaning, rust removal, and oxide layer elimination | Non-contact, environmentally friendly cleaning without chemical agents |

| Seam Processing | Seam trimming and finishing | Ensures high-quality weld seam appearance and strength |

| Control System | Embedded CNC system with touch screen | User-friendly interface with programmable welding parameters |

| Cooling Method | Water Cooling | Maintains stable laser operation temperature and prolongs machine life |

| Power Supply | AC 220V ±10%, 50/60Hz | Standard industrial power input |

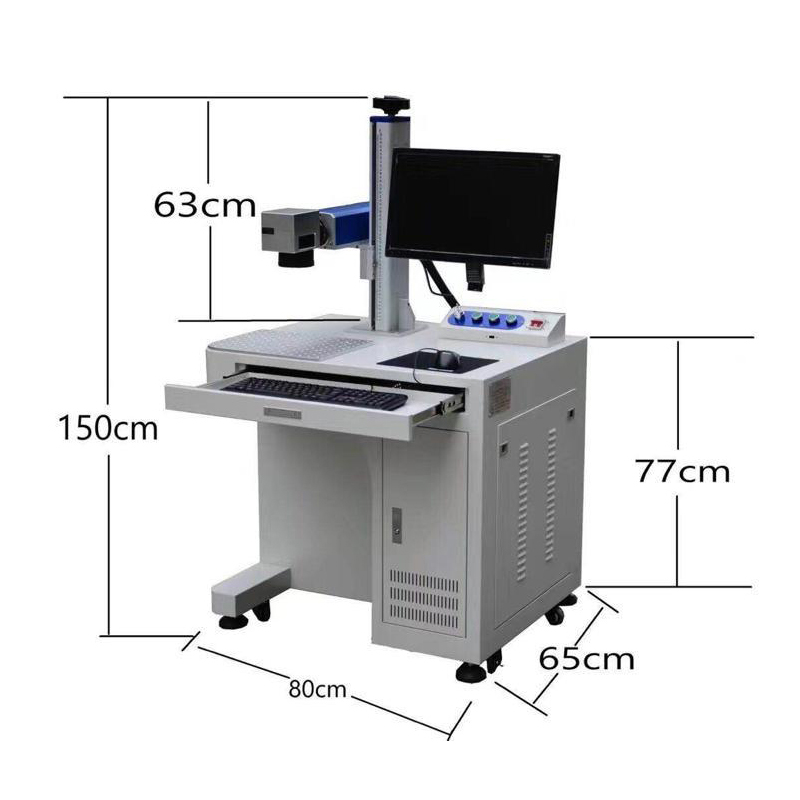

| Machine Dimensions | 1200 x 800 x 1500 mm (LxWxH) | Compact design suitable for workshop environments |

| Machine Weight | Approximately 250 kg | Stable structure ensuring minimal vibration during operation |

| Safety Features | Laser safety enclosure, emergency stop, protective interlocks | Ensures operator safety and compliance with industrial standards |

| Supported Materials | Stainless steel, carbon steel, aluminum, copper, titanium, brass | Wide range of metal materials for diverse welding and cutting needs |

| Software Compatibility | Supports CAD/CAM software and remote diagnostics | Easy integration into existing production lines and maintenance |

| Optional Accessories | Rotary axis, pneumatic clamps, fume extractor, vision system | Enhances welding precision and expands application possibilities |

|  |  |

|---|---|---|

| Control Panel Xinghong control system, with auto layout optimization, ensure high speed operation of whole machine. | Laser Source Chinese top brand fiber laser source Max, high power. The energy density is high, the heat input is low, the amount of thermal deformation is small. | Water Chiller S&A Water Chiller High cooling rate, which can weld fine weld structure and good joint performance. |