LASER in response to market demands and for the end-users of construction site pipe processing, has developed a portable and compact universal laser pipe cutting machine for round and square pipes.

This model has an extremely high cost-performance ratio. lt is a two-axis cutting equipment, featuring a rotating axis for the pipe and a rear-push type along the axial direction of the gun head. lt can support cutting various intersecting line-shaped cross-sections, as well as drilling and other technical operations (no beveling can be performed on the wall thickness). The system does not require programming and comes with a built-in graphic library. The operation is simple and straightforward.Conventional processing techniques do not require drawing.

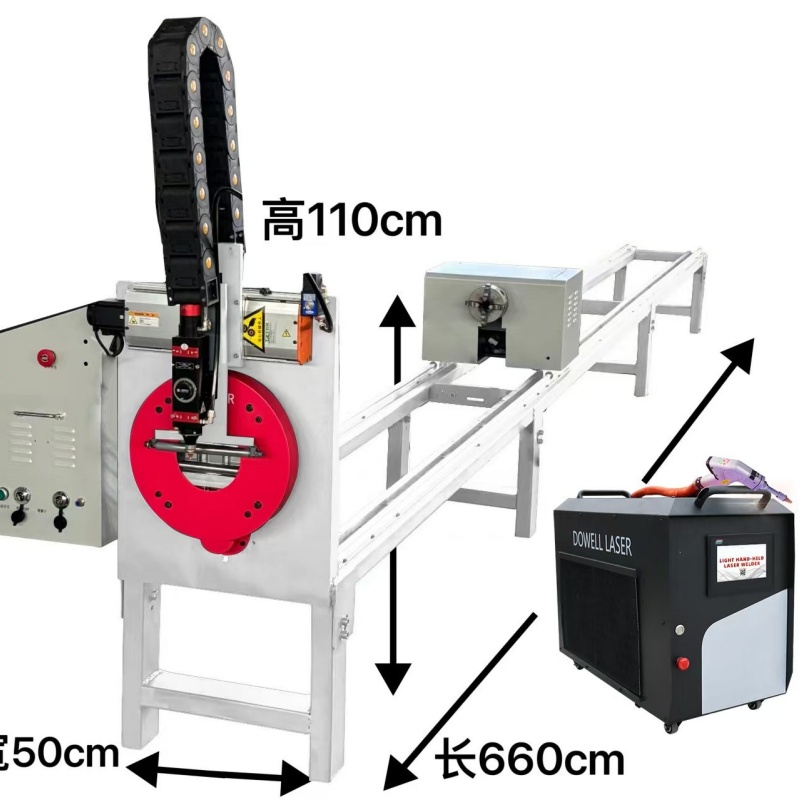

The conventional effective processing size of the pipe is 6 meters. The body can be disassembled into 3 segments, each 2.2 meters long, facilitating transportation.The size can be customized.

From the configuration selection to the assembly process, to the later training and after-sales service, this model truly creates a laser pipe cutting machine that customers can afford and use.in terms of transmission, it is equipped with precision gear racks, servo motors, and bilateral linear guides, which greatly enhance the stability and precision of the equipment and the high-quality cutting capability.

Technical parameters of the equipment

| Name | Technical Specifications |

| Effective cutting pipe diameter | Round pipe: 15 – 114 mm; Square or rectangular pipe: 15 – 120 mm |

| Cutting thickness | 2.5 mm (depending on the material and the power of the laser) |

| Effective cutting length of pipe material | 6150 mm |

| Load-bearing capacity of a single pipe | ≤60KG |

| Cutting accuracy error | + 0.3 mm |

| Cutting speed | Square tube: 0 – 7000mm/min; Round tube: 0 – 8000mm/min |

| Resetting accuracy | ±0.02mm |

| Equipment size | 68500mm*800mm*1200 mm(Subject to actual items) |

| Equipment weight | 300 KG |

| Power supply voltage | 220 V |

Main configuration Description

Laser generator

Compact and lightweight: Small in size, light in weight, the working position can be moved occupying a small area, and it is convenient to deploy in factories with limited space;

High electro-optical conversion efficiency: Conversion efficiency reaches over 30%,significantly reducing energy consumption, saving operating costs (such as electricity costs).and simultaneously improving production efficiency;

Low operation and maintenance costs:Only requires electrical power drive, reducing consumable costs; combined with maintenance-free design, the overall operating cost is the Lowest;

Maintenance-free and high stability: There are no optical lenses in the resonator cavity,no startup time required, no adjustment needed, and no maintenance required; the optical path is simple,reducing component costs and downtime.

Laser cutting head

This laser cutting head demonstrates significant advantages in medium and low power, small-sized fiber laser cutting applications;

Its internal structure adopts a fully sealed design, effectively preventing dust from contaminating the optical components;

The focusing mechanism employs a cam structure to ensure precise and convenient adjustment;

The protective lens is installed in a drawer-style manner,making the replacement operation extremely convenient.